"World Top Class Engineering Capability of Fabricated Parts" From sheet metal to finished part, From concept design to production

Technological capabilities and key products

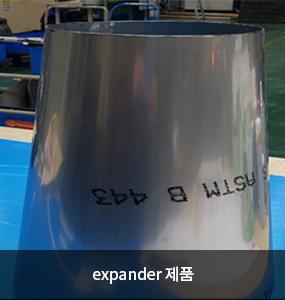

1. G/T Augment Liner

| Product Name | Engine Aug. Liner (After Burner) Component |

|---|---|

| Applicable Engine | F404/414, J85 engine, etc. |

| Major Process | Mechanical/Hydraulic Press, CNC Punch, Expander TIG / Resistance Welding, Vacuum Heat Treatment, TBC Coating, etc. |

| Material/Size | Haynes188, 700 D x 1500 L |

2. Helicopter IRS (Infra Red Suppression)

| Product Name | KUH IRS (Infra-Red Suppression) Component |

|---|---|

| Applicable Engine | KUH (Surion) Helicopter (System Component) |

| Major Process | Bladder Press, Drawing, Vacuum Heat Treatment, Laser-cut, Welding, H/W Assembly, etc. |

| Material/Size | Ni & Ti Alloy |

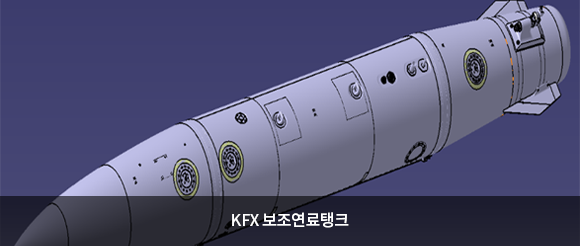

3. External Fuel Tank(In Development)

| Product Name | KFX External Fuel Tank (EFT) |

|---|---|

| Applicable Engine | KFX Fighter Jet (System Component) |

| Major Process | Press (Deep Drawing), Machining, Welding, Vacuum Heat Treatment, H/W Assembly, etc. |

| Material/Size | Al Alloy , 5,400 L x 670 D x 780 H |

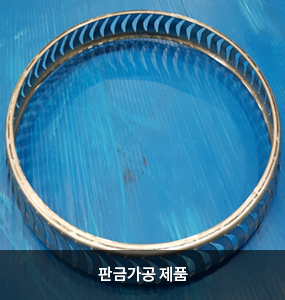

4. Combined Power Generation G/T Component Development and Repair

| Product Name | T/B Nozzle, SEAL |

|---|---|

| Applicable Engine | Large/Small Combined Power Generation Gas-Turbine |

| Major Process | Laser-cut, TIG Welding, Hydraulic Press, Vacuum Heat Treatment, Coating, EDM, etc. |

| Material/Size | Various Heat Resistant Alloys (Ni Alloy), Formations |

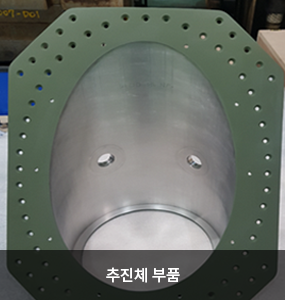

5. Propellant H/W Development

| Product Name | Oil Sump Tank, Etc. |

|---|---|

| Applicable Engine | Space Launch Vehicle and Propulsion Unit Component |

| Major Process | Laser-cut, TIG Welding, Milling, Rolling, Leak Test, etc. |

| Material/Size | Fe Alloy(SUS 316), 230 x 70 x 120 |